Infrastructure Facilities

The Production facilities are equipped with sophisticated machines and the latest technology. Our highly skilled and qualified machine operators with vast experience do a host of precision machining processes: milling, boring, threading, thread and gear cutting, counter boring and counter sinking, pocketing, facing, and reaming, to transform the most complex engineering drawing into a high quality product.

Divisions of CKB Group

CKB PRECIWAY ENGINEERING PVT LTD

UNIT I Conventional Machining Unit

We at CKB GROUP are Well Specialized in the Conventional Machining Operations like Drilling, Milling, Boring and Lathe Operations.

| S. NO | DESCRIPTION | MAKE | MACHINE SPECIFICATION | ||

|---|---|---|---|---|---|

| MILLING MACHINES | SIZE | TRAVEL AXIS (XxYxZ Axis in Meter) | CAPACITY | ||

| 1 | PLANOMILLER WITH DRO | BOEHRINGER | ISO 50 | 5M x 2M x 1.25M | 15 HP |

| 2 | PLANOMILLER WITH DRO | EGAMILL | ISO 50 | 3M x 0.75M x 1.5M | 10 HP |

| 3 | UNIVERSAL MILLING MACHINE | HURON | ISO 30 | 2M x 1.5M x 0.75M | 7.5 HP |

| LATHE MACHINES | SIZE | TRAVEL AXIS (XxYxZ Axis in Meter) | CAPACITY | ||

| 4 | HEAVY DUTY LATHE | HERBET-9C | 20” | 1.2 M | 7.5/15 HP |

| 5 | CENTRE LATHE | MMM | 16” | 1.5 M | 7 HP |

| 6 | LATHE MACHINE | YANG | 12” | 1.0 M | 5 HP |

| DRILLING MACHINES | SIZE | ARM LENGTH (in Meter) | CAPACITY | ||

| 7 | RADIAL DRILL – CESPEL | CESPEL | 5” | 2.5M | 7 HP |

| 8 | RADIAL DRILL – RABOMA | MMM | 16” | 1.5 M | 7 HP |

| 9 | RADIAL DRILL – HMT RM 65 -3 | HMT | 3” | 2.3 M | 5 HP |

| 10 | RADIAL DRILL – HMT RM 65 -2 | HMT | 3” | 2.3 M | 5 HP |

| 11 | RADIAL DRILL – HMT RM 65-1 | HMT | 3” | 2.3 M | 5 HP |

| 12 | RADIAL DRILL – HMT RM 63 | HMT | 2.5” | 2 M | 5 HP |

| 13 | RADIAL DRILL – HMT RM 62 | HMT | 2” | 1.8 M | 5 HP |

| 14 | RADIAL DRILL – HMT RM 60 | HMT | 1.5” | 1.5 M | 5 HP |

| 15 | RADIAL DRILL – HERMAN KOLB | HERMAN KOLB | 3” | 1.5 M | 7 HP |

| 16 | PILLAR DRILLING MACHINE | PETLER | 2” | – | – |

| 17 | TOOL & CUTTER | PRAGA 411 | – | – | 3 HP |

| WELDING MACHINES | SIZE | TRAVEL AXIS (XxYxZ Axis in Meter) | CAPACITY | ||

| 18 | ARC WELDING MACHINE | RILION | – | – | 250 Amps |

| 19 | TIG & ARC WELDING MACHINE | KORE | – | – | 400 Amps |

| 20 | MIG WELDING MACHINE | SAI MIG-400D | – | – | 400 Amps |

| 21 | MIG WELDING MACHINE | SUN POWER-500 | – | – | 500 Amps |

| 22 | MIG WELDING MACHINE | RILION 500 | – | – | 500 Amps |

|

OTHER FABRICATION FACILITIES |

SIZE | TRAVEL AXIS (XxYxZ Axis in Meter) | CAPACITY | ||

| 23 | HYDRAULIC PRESSING MACHINE | SHARADA | – | – | 500 TON |

| 24 | BACK SPOT FACING MACHINE | KING | 2” | – | 2 HP |

| 25 | POWER SAW CUTTING MACHINE | M.M | 10” | – | 3 HP |

| 26 |

AIR COMPRESSOR |

ELGI | 500 Ltrs | – | 5 HP |

| 27 | AIR COMPRESSOR | ELGI | 750 Ltrs | – | 7.5 HP |

UNIT II & III Sheet Metal & Heavy Fabrication Unit

We at CKB GROUP are Well Specialized in the Sheet metal & Heavy Fabrication Process of Gas Cutting, Laser Cutting, Grinding, Manual Welding & Robotic Welding (Tig, Mig & Arc)

| WELDING MACHINES | CAPACITY | ||

|---|---|---|---|

| 1 | ARC WELDING MACHINE | RILION | 250 Amps |

| 2 | TIG & ARC WELDING MACHINE | KORE | 400 Amps |

| 3 | MIG WELDING MACHINE | SAI MIG-400D | 400 AMPS |

| 4 | MIG WELDING MACHINE | SUN POWER-500 | 500 AMPS |

| 5 | MIG WELDING MACHINE | RILION 500 | 500 AMPS |

| FEW FABRICATION FACILITIES | CAPACITY | ||

|---|---|---|---|

| 1 | HYDRAULIC PRESSING MACHINE | SHARADA | 500 TON |

| 2 | BACK SPOT FACING MACHINE | KING | 2 HP |

| 3 | POWER SAW CUTTING MACHINE | M.M | 3 HP |

| 4 | AIR COMPRESSOR | ELGI | 5 HP |

| 5 | AIR COMPRESSOR | ELGI | 7.5 HP |

SRI FORTUNE ENGINEERING CORPORATION

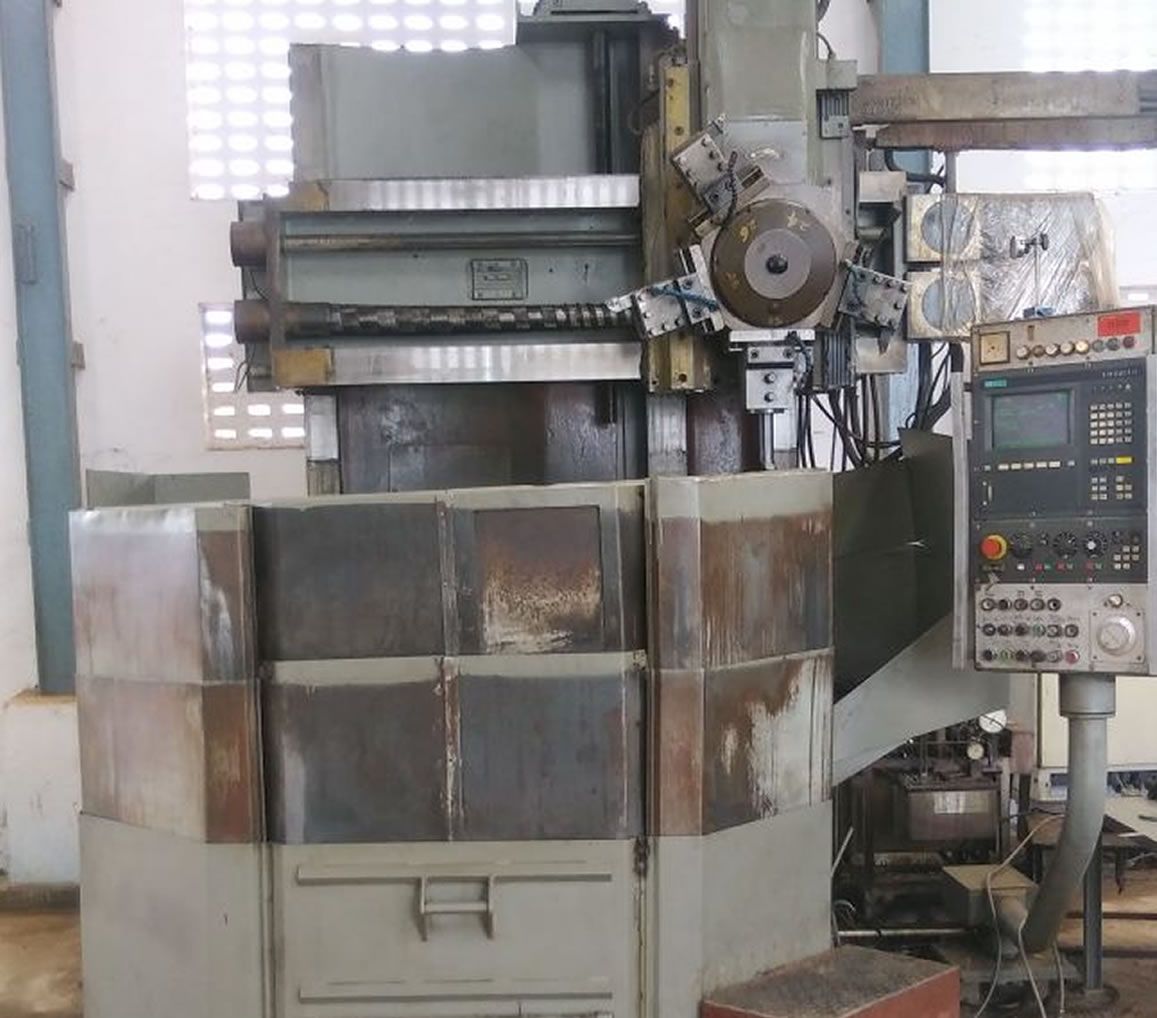

UNIT I & II PRECISION & HEAVY CNC DIVISION

We at CKB GROUP are Well Specialized in the Precision and CNC Machining Operations like Drilling, Milling, Boring and Turning.

| DESCRIPTION | MAKE | MACHINE SPECIFICATION | ||||

|---|---|---|---|---|---|---|

| CNC (TURNING) MACHINES | CHUCK DIA | SWING DIA / Z-AXIS (in Millimeter) | CAPACITY | |||

| 28 | VERTICAL TURNING LATHE WITH DRO | SCHIESS | CHUCK DIA 2000 | SWING DIA: 2300mm, Z Axis: 1600mm | 25 HP | |

| 29 | VERTICAL TURNING LATHE | DEFUM | CHUCK DIA 1100 | SWING DIA: 1400mm, Z Axis: 1000mm | 15 HP | |

| 30 | HORIZONTAL TURNING LATHE | MONFORD | CHUCK DIA 250 | SWING DIA: 350mm, Z Axis: 1000mm | 15 HP | |

| CNC (MILLING) MACHINES | SIZE | TRAVEL AXIS (XxYxZ Axis in Millimeter) | CAPACITY | |||

| 31 | VERTICAL MACHINING CENTRE WITH 4th AXIS | JYOTI – 1260 | BT 50 | Table Size: 1400mm x 630mm 1230mm x 600mm x 610mm | 11/15 KW | |

| 32 | VERTICAL MACHINING CENTRE WITH 4th AXIS | HURCO VMX84 | BT 50 | Table Size: 2184mm x 845mm 2134mm x 864mm x 762mm | 18/22 KW | |

| 33 | DOUBLE COLUMN MACHINING CENTRE WITH 5 FACE AXIS | "V-TEC VF-3026" | BT 50 | Table Size: 3200mm x 2000mm 3200mm x 2700mm x 1000mm | 25/29 KW | |

| 34 | HORIZONTAL BORING CENTRE | ROSS110 | ISO 50 | Table Size: 1200mm x 1200mm 2000mm x 1500mm x 1250mm | 18/22 KW | |

| SUPPORTING MACHINE | SIZE | RESOLUTION (XxZ Axis in Millimeter) | RANGE (in Millimeter) | |||

| 35 | TOOL PRE SETTER WITH CAMERA MODEL | PSTV – 6040 | BT 50 | 0.005mm x 0.005mm | Dia: 0 – 600 mm Length: 0 – 400 mm | |

| SUPPORTING MACHINE | SIZE | TRAVEL AXIS | CAPACITY | |||

| 36 | EDM DRILL MACHINE | 10 mm | 350mm x 285mm x 310mm | 5 AMPS | ||

| TESTING FACILITIES | ||||||

|

EQUIPMENT |

SIZE | ACCURACY | MEASUREMENT | |||

| 37 | COORDINATE MEASURING MACHINE | FARO PRIME | 3M (10feet) | 0.042mm | 0.059mm | 3D |

| DESCRIPTION | MAKE | MACHINE SPECIFICATION | |||||

|---|---|---|---|---|---|---|---|

| CNC (TURNING) MACHINES | CHUCK DIA | SWING DIA / Z-AXIS (in Millimeter) | CAPACITY | ||||

| 1 | VERTICAL TURNING LATHE | TOS / SKJ 12 CNC | CHUCK DIA 1250 | SWING DIA: 1400mm, Z Axis: 1150mm | 10 HP | 13000 Kgs | |

| 2 | ROBOTIC WELDING MACHINE | KUKA-210 | – | Arm length : 2500M | 530 Amps | 200 Kgs | |